Automatic Tape Edge Machine VS Semi-Auto Tape Edge Machine

- By:Zhonglian

- 2024-06-27

- 48

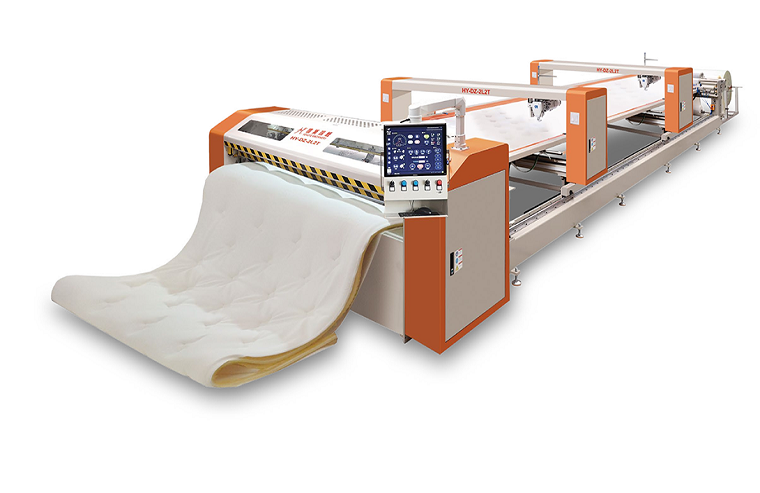

One of the most critical steps in mattress production is the mattress tape edging part, and the number of mattresses sewn by the staff in a day directly affects the cost. With the progress of science and technology, the emergence of mattress tape edge machines has greatly improved production efficiency.

About Mattress Tape Edge Machine Types

There are two popular types on the market: the first we call semi-automatic mattress tape edge machines, and the other we call automatic mattress tape edge machines that we are discussing now. Both of these mattress tape edge machines have their own advantages.

Semi-automatic mattress tape edge machines usually require some degree of manual operation. Operators need to manually adjust and guide the mattress to ensure the accuracy of the edging process. This type of equipment is very suitable for small-scale production and limited budgets. Its main advantage is that the initial cost is low, suitable for some small enterprises and handmade workshops.

However, compared with semi-automatic mattress tape edge machine, automatic mattress tape edge machine has more advantages. Because we improved a lot of things. For example, it can reduce labor costs and the operation is less complicated. You only need to control the PLC system to establish the settings when we operate the automatic mattress tape edge machine, incredibly easy for the operator to use.

Advantages of Automatic Mattress Tape Edge Machine

Automatic mattress tape edge machine adopts PLC program control and artificial intelligence operation. When we sew the mattress, it can walk automatically during the sewing process. This automated operation not only improves production efficiency, but also reduces the occurrence of human error.

In addition, it also automatically corners, automatically turns, and increases sewing speed. This means that when handling the corners of the mattress, the operator does not need to manually intervene, and the device adjusts the angle and position on its own.

We have also added a lot of functions, such as the mechanical head can automatically lift and slow down at the corner, and automatically recover at the corner of the stitched mattress. This function effectively solves the common problem of the four corner seams of the mattress protruding inward.

The automatic mattress tape edge machine is suitable for factories that require a large number of mattresses every day. Sewing mattresses only need one person to operate, improve work efficiency, reduce labor intensity. It is the ideal equipment for high-end mattress manufacturing and assembly line production. If your company produces a large number of mattresses every day, automatic mattress tape edge machines will be the best choice for you.

Cost

The price of a mattress tape edge machine is easy to focus on, but what is the long-term cost of ownership? Buying the machine is simple, but what is the cost later? Mechanical repairs, downtime, are always painful. For example, are there parts that need to be replaced frequently? What if the machinery fails?

Therefore, it is particularly important to choose a reputable mattress machinery manufacturer. Zhonglian Machinery has a professional after-sales service team, committed to providing customers with a full range of support.

When your machine breaks down or parts are damaged, you do not have to worry, our team is able to respond quickly to provide you with repair services and the necessary supply of spare parts, ensuring that your production line will not be affected for a long time.

-

Automatic Tape Edge Machine VS Semi-Auto Tape Edge Machine

2024/06/27 -

Revolution of Computerized Multi-Needle Quilting Machine

2024/05/23 -

Is Lubrication Necessary for Mattress Sewing Machines?

2024/05/15 -

How Mattress Packaging Machine Boosts Packaging Speed ?

2023/01/06 -

Mattress Automation with Tape Edge Machine

2022/04/20 -

How to Choose Mattress Sewing Machine

2022/04/20